Industrial Internet of Things

The Industrial Internet of Things (IIoT) has a transformative impact on the power grid by leveraging connected devices, sensors, and advanced analytics to enhance the operation, management, and efficiency of electrical infrastructure. Here’s a brief overview of its impact

Impact of IIoT on the Power Grid

Enhanced Monitoring and Control

Real-Time Data: IIoT enables real-time monitoring of grid components such as generators, transformers, and distribution lines through connected sensors. This provides valuable insights into system performance and health.

Remote Control: Operators can remotely manage and adjust grid operations, improving response times and operational flexibility.

Improved Grid Reliability and Efficiency

Predictive Maintenance: IIoT data analytics predict equipment failures before they occur, allowing for proactive maintenance and reducing unplanned outages.

Optimized Operations: Advanced algorithms analyze data to optimize energy distribution, reduce losses, and balance supply and demand more effectively.

Enhanced Integration of Renewable Energy

Dynamic Adjustment: IIoT systems help manage the variable nature of renewable energy sources by dynamically adjusting grid operations and integrating distributed energy resources seamlessly.

Demand Response: IIoT enables more effective demand response strategies, adjusting consumption based on real-time grid conditions and renewable generation.

Advanced Grid Management

Smart Grids: IIoT supports the development of smart grids with advanced features like automated fault detection, self-healing capabilities, and real- time load management.

Data-Driven Decisions: The vast amount of data collected through IIoT allows for better-informed decisions regarding grid operation, planning, and infrastructure investments.

Enhanced Security

Cybersecurity: IIoT devices include advanced security features that help protect the grid from cyber threats, ensuring the integrity and reliability of critical infrastructure.

Anomaly Detection: Real-time data analytics can identify and respond to unusual patterns or potential security breaches more rapidly.

Operational Cost Reduction

Efficient Resource Utilization: By providing detailed insights into system performance, IIoT helps optimize the use of resources, reducing operational and maintenance costs.

Challenges and Mitigations

Data Management

The large volume of data generated requires robust storage and analysis capabilities. Investing in scalable data infrastructure and analytics tools can address this challenge.

Integration Complexity

Integrating IIoT with existing grid infrastructure can be complex. A phased approach and interoperability standards can facilitate smoother integration.

Cybersecurity Risks

With increased connectivity comes greater risk of cyber threats. Implementing strong security protocols and continuous monitoring can help safeguard the grid.

Overall, IIoT significantly enhances the power grid’s operational efficiency, reliability, and flexibility, supporting the transition to a more resilient and sustainable energy system.

As a Consultant and Solution Provider in the Industrial Internet of Things (IIoT) field, PolluxCorp can offer the following comprehensive services and product solutions to help businesses optimize, secure, and scale their IIoT ecosystems:

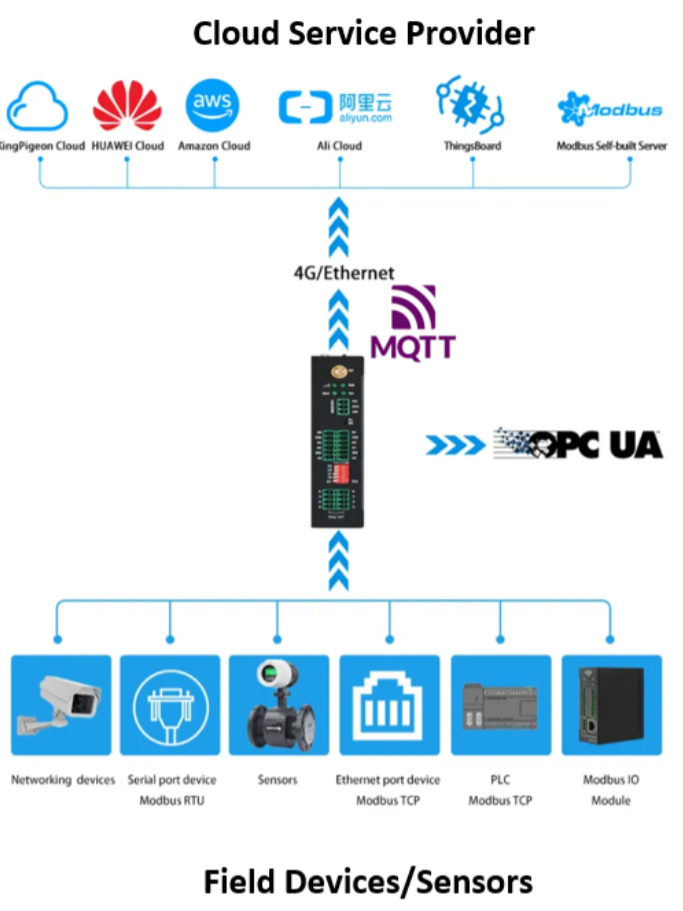

IIoT Infrastructure Design and Deployment

Network Architecture Design: Build robust, low-latency, and highly secure network infrastructures for IIoT deployments.

Edge Computing Solutions: Design and implement edge computing frameworks for real-time data processing close to the source.

Cloud Integration: Ensure seamless integration of IIoT data with cloud platforms for advanced analytics and remote management.

Device and Sensor Management

Sensor Deployment and Configuration: Help with the installation, configuration, and calibration of IIoT sensors and devices.

Device Lifecycle Management: Establish a system to manage devices from

onboarding to decommissioning.

Firmware and Software Updates: Implement automated processes for regularly updating device firmware and software to improve functionality and security.

Industrial Connectivity and Protocol Integration

Protocol Standardization: Enable seamless communication between IIoT devices using protocols like MQTT, OPC UA, and Modbus.

Interoperability Solutions: Ensure different devices and systems from multiple vendors work together without compatibility issues.

4G, 5G and LPWAN Deployment: Assist in deploying advanced communication technologies like 4G, 5G or Low-Power Wide-Area Networks (LPWAN) for high-bandwidth or long-range connectivity.

Edge and Real-Time Processing

Edge Processing: Deploy models on edge devices to process real-time data, reducing latency and improving responsiveness.

Real-Time Monitoring: Implement systems for real-time monitoring and

alerting based on edge data, minimizing critical delays.

Remote Management and Monitoring

Condition-Based Monitoring: Implement monitoring systems that trigger alerts based on specific conditions like temperature, pressure, or vibration.

Remote Control and Automation: Enable remote control capabilities for key industrial processes, reducing on-site interventions.

Training and Capacity Building

IIoT Technology Training: Provide in-depth training for operational staff on IIoT technologies, platforms, and security protocols.

Change Management: Help organizations navigate the cultural and operational changes required to successfully adopt IIoT technologies.

By offering these comprehensive services, you can empower businesses to leverage the full potential of IIoT for smarter, more efficient, and secure industrial operations.